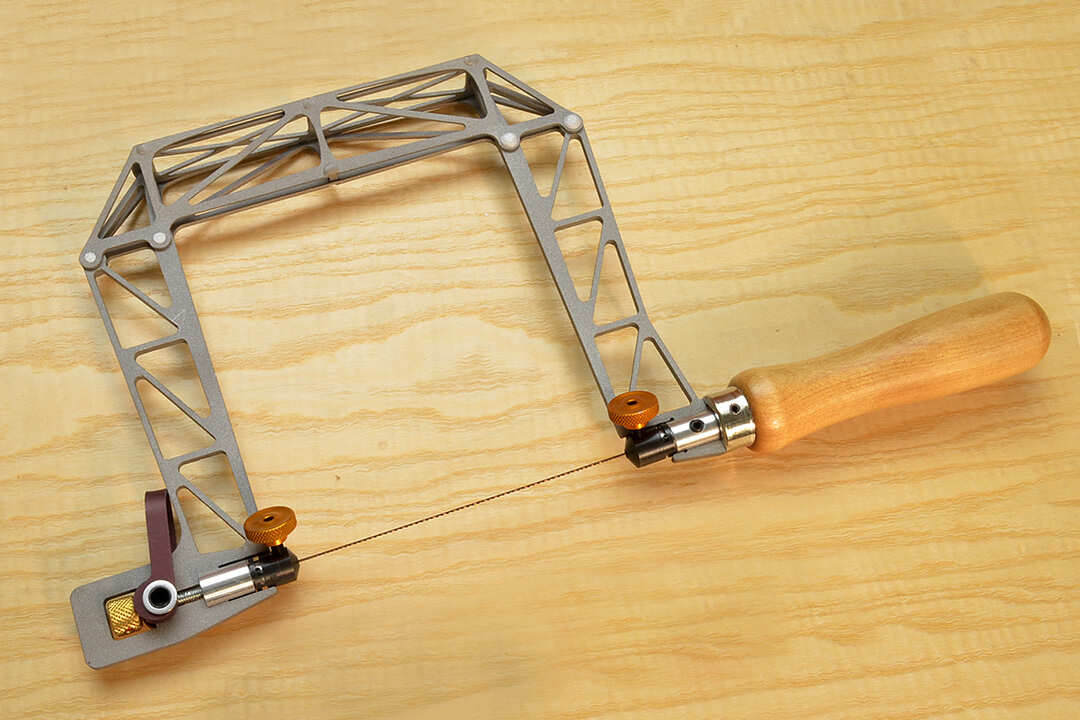

Adam Savage Loves Knew Concepts Saws

Posted by Admin on 11th Jul 2013

HOW TO SELECT THE RIGHT BLADES FOR YOUR KNEW CONCEPTS SAW:

Just like bandsaws and tablesaws, your jewelers fretsaw frame changes personality depending upon the type of blade you have installed. With the right blade you will get fast, smooth easy sawing and a clean finish.

Knew Concepts recommend Pegas Swiss-made sawblades, so at Workshop Heaven we decided to stock the entire Pegas range in packs of 12 blades - so you can get your saw and the blades in one transaction. The more popular flavours are now also available in packs of 144 blades. The Pegas range of 5" unpinned blades is huge, so here's a few pointers to help you select the appropriate blade for the job.

Choosing the right tooth pattern

For dovetailing: Skip reverse blades

These have plenty of gullet space to clear the waste and a patch of reversed teeth at the end of the blade, which gives you an entry quality cut on both faces. There are only four sizes and a pack of each will cover the normal range of material thicknesses used in furniture making.

For Jump rings and thin sheet metal: Regular tooth metal cutting blades

Fine blades with a regular tooth pattern to give a smooth cut and a beautiful finish. Always get blades with a rounded back as they are easier to turn and less prone to breakage.

For Marquetry and fretwork: Spiral blades

The blade is twisted into a helix so it can cut in any direction. Tricky to hold a straight line, but much easier for following curved ones. Because you don't need to orientate the frame to the work you can still cut in any direction when working close to the full depth of the frame.

For cutting soft materials: Skip tooth blades

Softer materials produce swarf more rapidly than hard ones, skip tooth blades have gaps between the teeth to carry the extra material away without clogging the saw.

Double skip and modified geometry blades have even bigger gaps, and so require a higher reciprocation speed. Although they are wonderful in powered scroll saws, these two types are not really appropriate for use in Knew Concepts hand frames.

Choosing the right pitch (number of teeth per inch)

A good rule of thumb is to have between three and twelve teeth engaged in the material at any given moment, with optimum performance at 7 or 8 teeth.

For example if you are cutting 1/8" (3mm) thick material you would want to be around the 20 to 23 teeth per inch mark. For harder materials like steel, go a little finer; for soft materials like wood and plastics a little coarser.

Blades for Knew Concepts Coping Saws

Chunkier frame = chunkier blades.

Knew Concepts coping saws use 6.5" pinned coping saw blades, these are larger and have a transverse pin running through the blade at either end to transfer the tension from the frame to the blade.

If you have any questions, please feel free to ask, we are always happy to help.

Happy sawing...!